When Ordering Please Specify:

1. Pipe Size

2. Pressure Rating

3. Perforation or Mesh Size

4. Material

5. Style

Temporary Strainers are primarily designed for short periods of operation;

for example during commissioning and initial start up of new or reconditioned process lines to remove any construction debris such as rags, welding rods pipe scale, rust etc., accidentally or unavoidably present within the system.

For ease of installation and removal of the strainer; a spool piece of the appropriate length fitted to the Process line would be advantageous.

Flow can be either direction; although from a structural point: Flow on to the point is considered by many, to be the better option.

| Nominal Pipe Size | I.D. Std wt | O.D. 150 # ANSI | O.D. 300 # ANSI | O.D. 600 # ANSI | O.D. 900 # ANSI | O.D. 1500 # ANSI | D |

|---|---|---|---|---|---|---|---|

| 20mm | 15 | 54 | 63 | 63 | 66 | 66 | 10 |

| 25mm | 19 | 63 | 70 | 69 | 76 | 76 | 15 |

| 40mm | 32 | 82 | 92 | 92 | 95 | 95 | 20 |

| 50mm | 46 | 102 | 108 | 108 | 140 | 140 | 25 |

| 65mm | 57 | 120 | 127 | 127 | 162 | 162 | 30 |

| 80mm | 70 | 133 | 145 | 146 | 165 | 171 | 40 |

| 100mm | 95 | 171 | 178 | 190 | 203 | 206 | 50 |

| 125mm | 117 | 193 | 210 | 238 | 244 | 251 | 65 |

| 150mm | 137 | 220 | 245 | 264 | 283 | 279 | 80 |

| 200mm | 187 | 276 | 305 | 317 | 355 | 349 | 100 |

| 250mm | 238 | 336 | 359 | 397 | 432 | 432 | 125 |

| 300mm | 279 | 406 | 420 | 454 | 495 | 517 | 150 |

| 350mm | 311 | 448 | 480 | 489 | 517 | 575 | 180 |

| 400mm | 355 | 511 | 535 | 562 | 571 | – | 205 |

| 450mm | 400 | 545 | 590 | 610 | 635 | – | 230 |

| 500mm | 444 | 603 | 650 | 679 | – | – | 255 |

| 600mm | 540 | 714 | 770 | 785 | – | – | 305 |

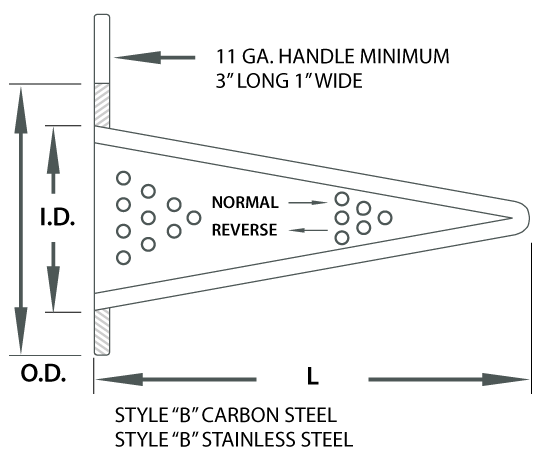

CONE TYPE:

Based on 3mm Ø HOLES ON 5mm CENTERS

| Nominal Pipe Size | Standard L | L-150% | L-200% |

| 20 | 50 | – | – |

| 25 | 50 | – | – |

| 40 | 70 | – | 75 |

| 50 | 75 | – | 100 |

| 65 | 80 | – | 115 |

| 80 | 90 | 100 | 140 |

| 100 | 100 | 125 | 180 |

| 125 | 125 | 165 | 230 |

| 150 | 150 | 200 | 280 |

| 200 | 155 | 250 | 355 |

| 250 | 190 | 315 | 460 |

| 300 | 230 | 375 | 510 |

| 350 | 255 | 405 | 535 |

| 400 | 255 | 465 | 585 |

| 450 | 305 | 530 | 685 |

| 500 | 355 | 600 | 790 |

| 600 | 410 | 720 | 940 |

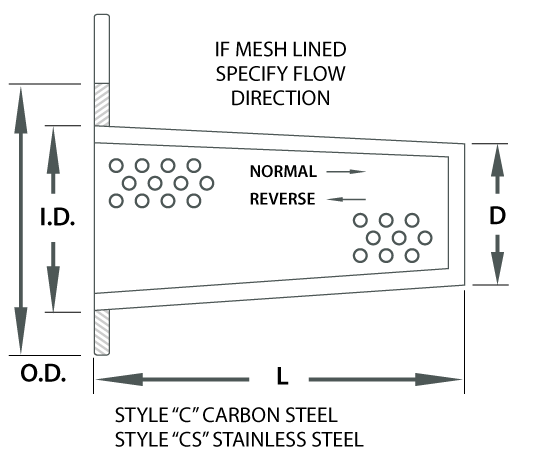

BASKET TYPE:

Based on 3mm Ø HOLES ON 5mm CENTERS

| Nominal Pipe Size | STANDARD L | L-150% | L-200% |

| 20 | 50 | – | – |

| 25 | 50 | – | – |

| 40 | 70 | – | 75 |

| 50 | 75 | – | 100 |

| 65 | 80 | – | 115 |

| 80 | 90 | 100 | 140 |

| 100 | 100 | 125 | 180 |

| 125 | 125 | 165 | 230 |

| 150 | 150 | 200 | 280 |

| 200 | 155 | 250 | 355 |

| 250 | 190 | 315 | 460 |

| 300 | 230 | 375 | 510 |

| 350 | 255 | 405 | 535 |

| 400 | 255 | 465 | 585 |

| 450 | 305 | 530 | 685 |

| 500 | 355 | 600 | 790 |

| 600 | 410 | 720 | 940 |

Percent open areas shown are compared to the cross sectional flow area of Standard Weight Pipe.

All dimensions are in mm.

Standard length is designed to fit weld neck raised face flange plus long radius butt weld elbow.

OD is designed to fit inside flange bolt hole circle.

Full face is available on request.

ID is designed to fit inside standard weight ( S40 ) pipe for 150# and 300# rating, extra strong ( S80 ) pipe for 600# rating.

If ordering this product please advise pipe schedule.